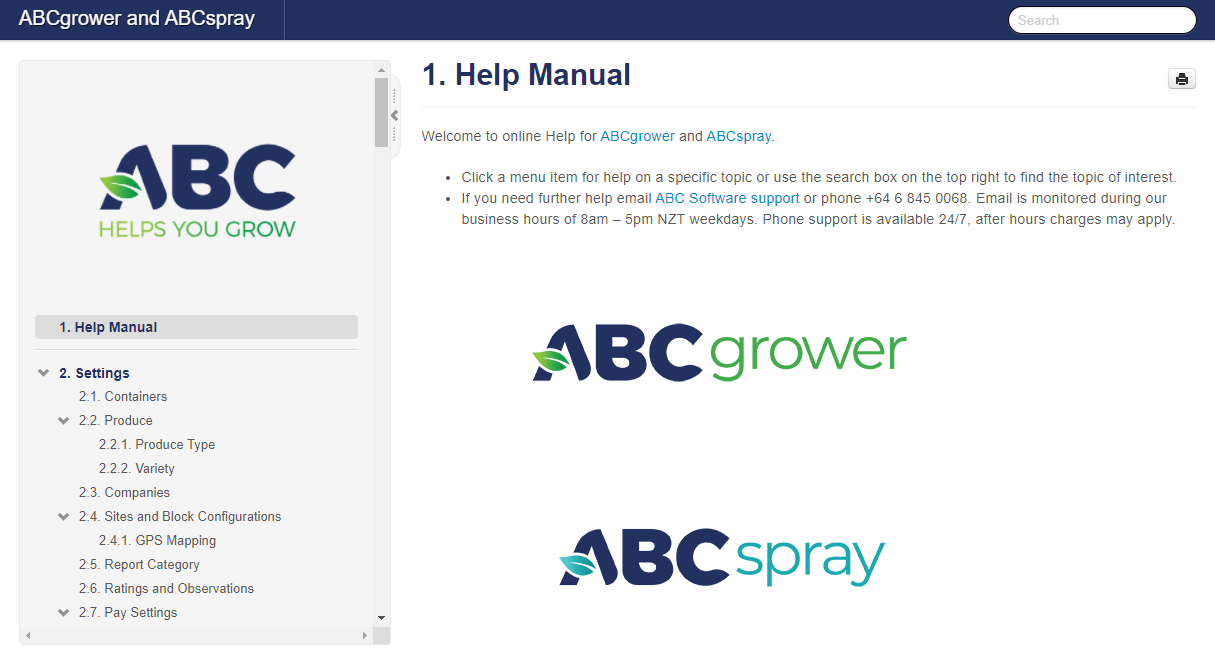

Help!

We’re excited to let you know we have released a brand spanking new online Help manual. It’s comprehensive, up-to-date and covers all modules in ABCgrower and ABCspray.

Where is it?

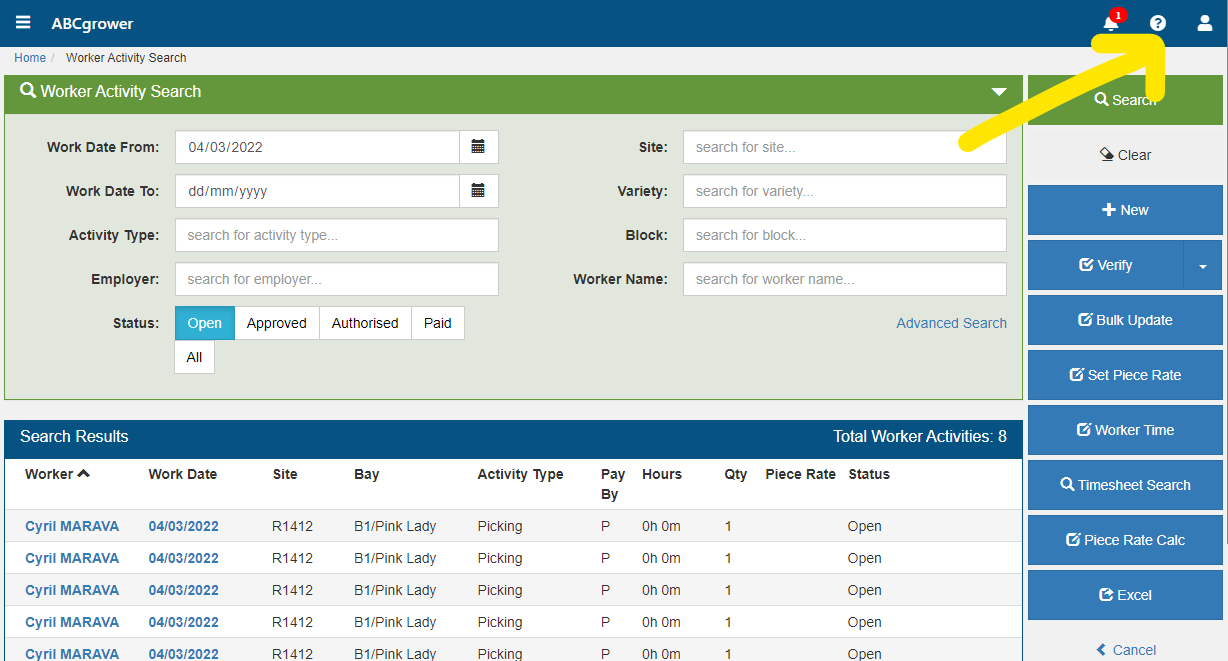

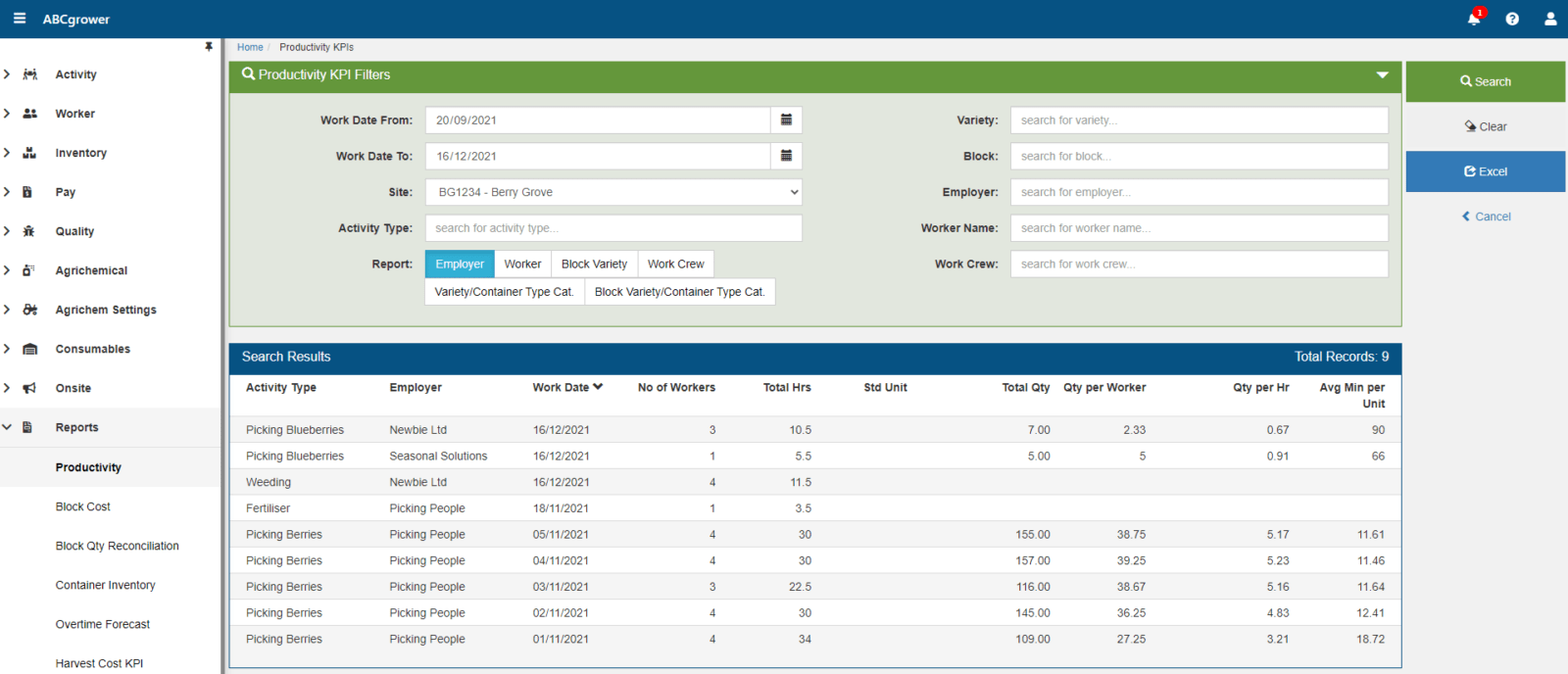

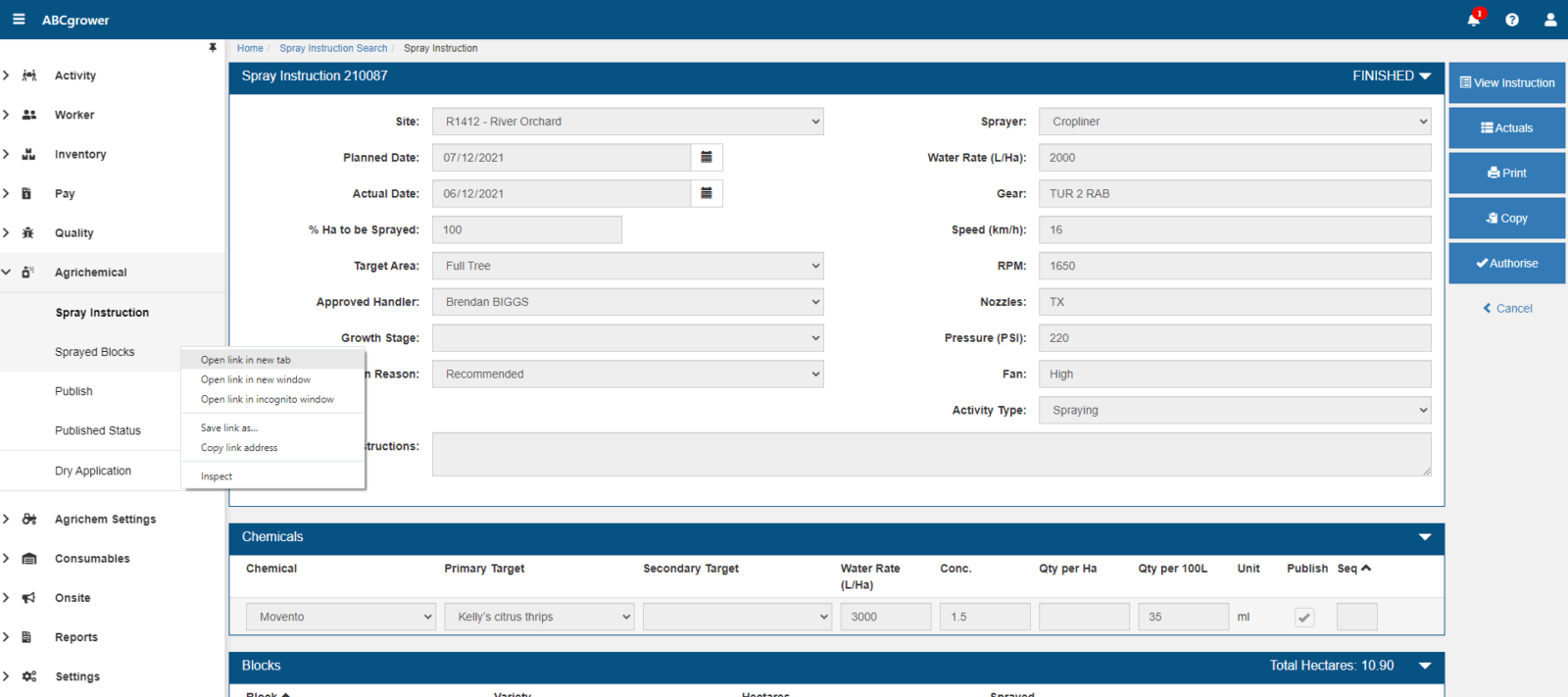

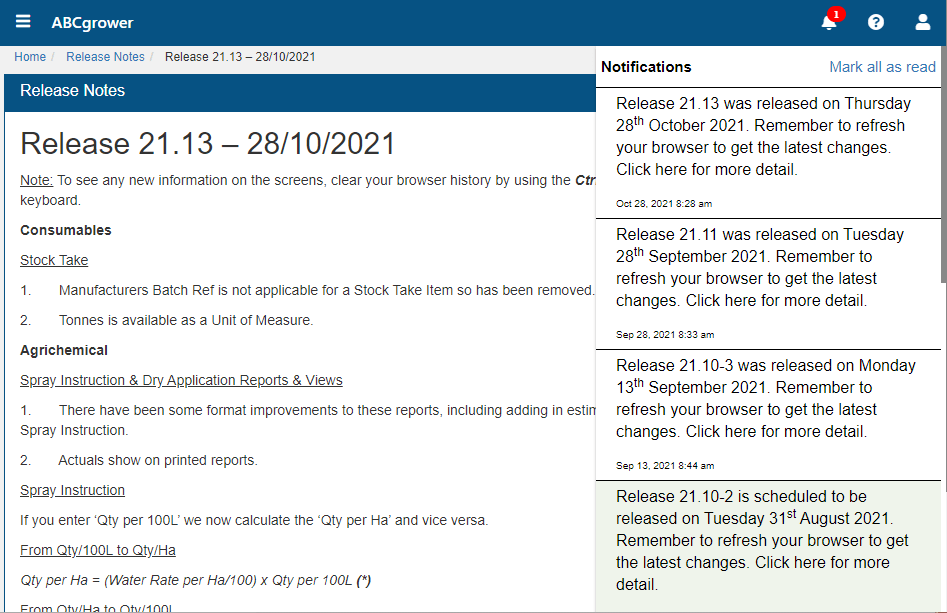

It’s accessed the same way as the existing manual. Click the question mark icon to the right of the top blue banner in ABCgrower. Whether you consider Help manuals your first port of call, or your place of last resort, check it out, it is helpful!